GMG Unveils G® Lubricant Engine Performance Testing Results: A Transformative Graphene Energy Saving Solution

BRISBANE, QUEENSLAND, AUSTRALIA – Graphene Manufacturing Group Ltd. (TSX-V: GMG) (OTCQX: GMGMF) (“GMG” or the “Company”) is pleased to announce the results of the multi-year performance testing of G® Lubricant, a transformative graphene liquid concentrate additive designed to enhance the performance of diesel and gasoline (petrol) engines. This product has the potential to reshape the future of the global liquid fuels industry and offers an innovative solution that optimizes efficiency and power for stationary or mobile engines.

Unleashing the Power of Graphene

G® Lubricant, a graphene liquid concentrate that can be added to any mineral or synthetic oil used in an internal combustion engine, has been shown to increase fuel efficiency by up to 8.4% in a diesel engine. The amount of graphene in the final lubricant once G® Lubricant is mixed in is only ~ 1:10,000, with the balance of the concentrate consisting of lubricating base oil. As a result, G® Lubricant can be used safely in any internal combustion engine. Over the past four years, GMG has conducted environmentally controlled testing of G® Lubricant in internal combustion engines monitored and verified by The University of Queensland. GMG’s test results have been corroborated by similar savings realized by customers over a number of years of field testing.

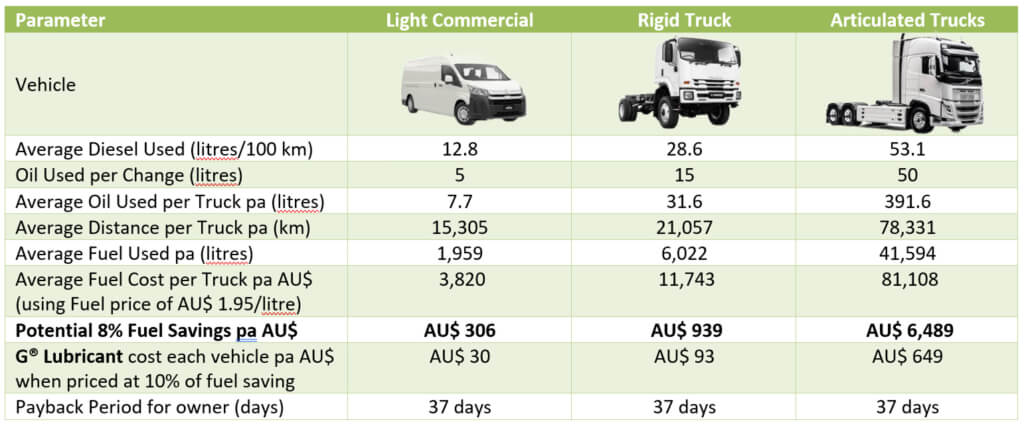

Figure 1 below shows the high level fuel efficiency improvement provided by the G® Lubricant additive.

Figure 1: Diesel Engine Fuel Efficiency Improvement provided by G Lubricant

The data shows a clear increase in fuel efficiency performance from G® Lubricant when the load is increased on the engine. High loads for truck diesel engines are usually seen when the truck starts to move, and then at high speeds when encountering wind resistance. Usually stationary diesel engines for power generation operate at high load.

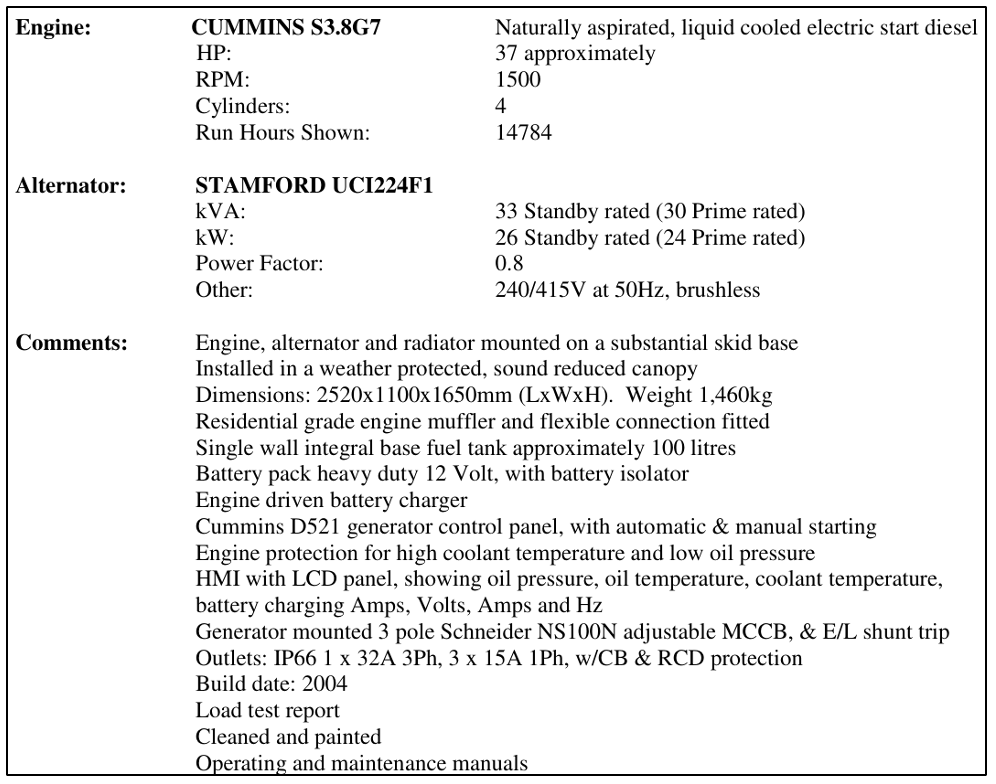

Figure 2 shows the potential savings for the main types of diesel engine commercial vehicles in use in Australia – with average vehicle data sourced from the Australian Bureau of Statistics[1] (ABS).

Figure 2: Potential Cost Savings per Vehicle Type provided by G Lubricant

Exceptional Performance Confirmed by University of Queensland

GMG’s Managing Director and CEO, Craig Nicol, commented: “G® Lubricant has taken over 4 years of advanced product testing and is transformational for energy efficiency and emissions reduction for the liquid fuels industry – it is the culmination of decades of lubricants, engines, energy markets and graphene knowledge which is inherent in the GMG business. The next challenge to commercialise this product awaits – which we are eagerly preparing for.”

GMG’s Chairman and Director, Jack Perkowski, commented: “G® Lubricant’s performance, which demonstrates an 8.4% improvement in fuel efficiency using only a very small amount of graphene in an easy to use graphene concentrate, is a ‘Category Creator’ that has the potential to redefine the multi trillion dollar liquid fuels market. The fact that only 1% of G® Lubricant is needed to achieve such savings provides a very attractive value proposition for fleet owners.”

Detailed Equipment and Process for Testing G® Lubricant

The following describes the equipment used and the process followed by the Company in demonstrating the fuel saving demonstration of the G® Lubricant in the diesel engine generator:

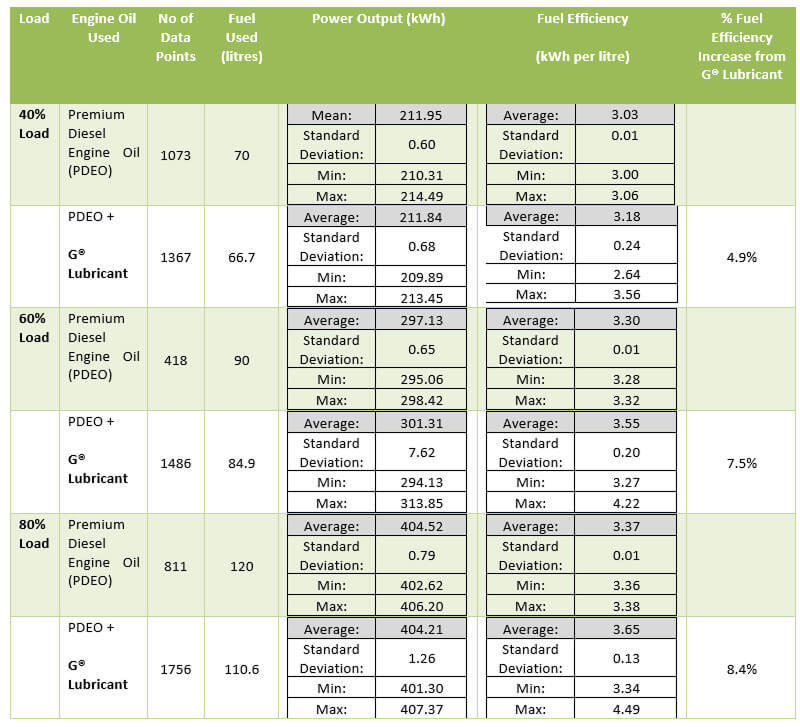

- A 30kVA (30 kW) Cummins diesel engine generator (with 14,784 hours of run time) as seen in Figure 5 and described in Figure 6 was purchased and setup in the GMG Richlands warehouse.

- The generator was connected to a 40 kW power load bank which consumed the energy produced by the generator and created the load and a 500 litre self-contained fuel tank.

- Two calibrated flow sensors were connected (inflow and return/outflow) to the fuel lines and to a data logger which recorded the fuel consumption.

- An Energy Analyzer was used to log and track energy produced by the generator.

- Tests were conducted on loads of 40%, 60% and 80% loads of the 40 kw power load bank – 12, 18, 24 kw respectively.

- A baseline to record diesel fuel consumption under normal engine oil and operating conditions was completed with newly changed recommended premium diesel engine oil and a new oil filter. This oil change was carried out by a professional engine maintenance service company.

- The engine was run at the different loads (40%, 60% and 80%) and the baseline and G® Lubricant data set used for the analytics is when the maximum ambient temperature for the day was less than 33 degrees Celsius and relative humidity was between 50% and 80% with no rain. Fuel consumption for diesel engines changes when operating in rain or very high humidity or temperatures, so the fuel consumption data baseline and G® Lubricant engine oil additive performance testing were excluded for these times.

- Only steady state data was used and so any variance or anomalous data seen in either baseline or G® Lubricant datasets were removed from the analytics. Data sets were grouped into minute blocks.

- Once the baseline fuel tests were completed, the engine oil was drained and the oil filters were replaced. G-Lubricant with approximately 1:100 concentration was mixed at approximately 1% ratio by weight with a new batch of the same premium recommended engine oil and added to the generator engine. The end ratio of GMG’s Graphene to the diesel engine oil was approximately 1:10,000 by weight. The oil change was carried out by the same professional engine maintenance service company.

G® Lubricant Packaging

G® Lubricant is currently sold by GMG in different small pack sizes, a 500 ml pack is shown in Figure 5 which can be diluted into 50 litres of engine oil to provide improved engine performance. GMG intends to direct market the product to its targeted markets through various pack sizes for direct and bulk use.

Figure 5: G® Lubricant 500 ml pack (which can be used to dose 50 litres of engine oil)

Figure 6: Diesel Engine Generator Equipment

Figure 7: Diesel Engine Generator Equipment Parameters.

Figure 8: Detailed Diesel Engine Generator Performance Data.

Basis for Performance Improvement

As seen in Figure 9, G® Lubricant GMG improves fuel efficiency by creating less friction in the boundary layer lubrication of the pistons inside the cylinder block of the engine. It is widely accepted that approximately 30% of the fuel is used in an engine to overcome internal friction, and that approximately 60% of the engine friction is in the piston area. Graphene has also been seen to prevent wear and also fill in wear scars of an engine, helping to improve piston sealing.

Figure 9: G® Lubricant is believed to reduce friction in the engine pistons.

Patent Progress of G® Lubricant

GMG submitted a patent application on the G® Lubricant product as soon as it was possible, and this is progressing through the usual process to be approved for the main target markets.

About GMG:

GMG is an Australian based clean-technology company which develops, makes and sells energy saving and energy storage solutions, enabled by graphene manufactured via in house production process. GMG uses its own proprietary production process to decompose natural gas (i.e. methane) into its natural elements, carbon (as graphene), hydrogen and some residual hydrocarbon gases. This process produces high quality, low cost, scalable, ‘tuneable’ and low/no contaminant graphene suitable for use in clean-technology and other applications.

The Company’s present focus is to de-risk and develop commercial scale-up capabilities, and secure market applications. In the energy savings segment, GMG has initially focused on graphene enhanced heating, ventilation and air conditioning (“HVAC-R”) coating (or energy-saving coating) which is now being marketed into other applications including electronic heat sinks, industrial process plants and data centres. Another product GMG has developed is the graphene lubricant additive focused on saving liquid fuels initially for diesel engines.

In the energy storage segment, GMG and the University of Queensland are working collaboratively with financial support from the Australian Government to progress R&D and commercialization of graphene aluminium-ion batteries (“G+AI Batteries”). GMG has also developed a graphene additive slurry that is aimed to improve the performance of lithium-ion batteries.

GMG’s 4 critical business objectives are:

- Produce Graphene and improve/scale cell production processes

- Build Revenue from Energy Savings Products

- Develop Next-Generation Battery

- Develop Supply Chain, Partners & Project Execution Capability

We invite you to explore the innovative world of graphene technology by visiting our website at https://graphenemg.com/. Discover how our cutting-edge solutions are transforming energy efficiency and battery performance.